MH Engineering: The Leading Pre-engineered Buildings Manufacturer in Dehradun:

Pre-engineered buildings depend on a large number of factors, such as the manufacturer, available transportation facilities, construction capacity, material costs, and labor costs. It includes various materials like precast concrete, wood, masonry blocks, steel sheets, glass curtain walls, etc.

If you are looking for an ideal pre-engineered building manufacturer in Dehradun then you can contact MH Engineering, as we cater to various forms and types of pre-engineered building structures in Dehradun. We offer our customers a variety of options that they can choose from. Each structure is made according to the customer’s specific requirements and detailed specifications. Quality materials are used to ensure its long-term durability.

You can visit our website and get detailed information and information about the components and types we offer in Dehradun.

Pre-engineered Buildings Structure in Dehradun:

In the field of structural engineering, pre-engineered buildings or (PEBs) are designed by a pre-engineered building supplier or a pre-engineered building manufacturer, which has a single design and is constructed using different materials and methods that allow a variety of satisfying structural and aesthetic designs. These PEBs are growing fast in Dehradun. A pre-engineered building is a building that is made of components that are manufactured in a factory and assembled at a specific site in Dehradun.

Typically, pre-engineered buildings are steel structures and can act as an alternative to traditional structural steel buildings. The components are machined to a precise size in the factory, transported to the site, and assembled on-site. These PEBs are growing rapidly in Dehradun. These are made with bolt connections. These are mainly used for pre-engineered building structures-

- structural steel framing system

- metal roofing system

- Wall panels made of different materials

To design an accurate structure of pre-engineered buildings, engineers consider wind uplift, bearing points, live load, roof slope, dead load, and a clear span among many other things. These Pre-engineered buildings can be adapted to suit a wide range of structural applications. This results in feasible savings in the structural frame and having a wide production in Dehradun.

Pre-engineered buildings are becoming rapidly popular nowadays in Dehradun because they overcome traditional buildings in terms of cost-savings and benefits of construction.

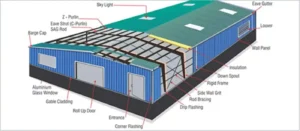

Components of Pre-engineered Building Structure in Dehradun:

The major components of pre-engineered buildings are divided into different types-

- Main framing or vertical columns: The mainframe consists of the steel rigid frame of the building. The rigid steel frame is made up of thin columns and thin rafters. These are manufactured using state-of-the-art technology while the flanges are welded.

- End wall framing: It is designed as the main rigid frame. The beam and wall system of framing consists of columns with pinned ends. These are known as the end wall rafters supporting the horizontal rafters.

- Purlins, girts, and eave struts: These are secondary cold-formed members of pre-engineered building components. No welding is required in this preparation. These are prepared by welding steel coils to the desired shape. The C-shape is for eave struts and the Z-shape is for purlins and girts.

- Crane System: The Crane system is used to improve material handling productivity, making greater use of space by reducing traffic caused by forklifts. The runway beam of the crane is supported by sections constructed with cap channels.

- Sheeting and insulation: Sheeting made of steel is usually a galvanized profiled sheet that is permanently painted. The sheets are also coated with special paint for better anti-corrosive properties. These are insulated through insulation slabs and steel sheets are fixed over it in the form of roofing steel sheets.

- Mezzanine System: In architecture, a mezzanine or entresol is an intermediate floor between the main floors of a building and so is not usually counted as a building’s total floors.

- Paint and Finish: Pre-painted steel is produced on modern high-speed coil painting lines, where surface preparation before painting and paint curing is carried out on a highly automated line under optimum conditions.

Advantages of Pre-engineered Building Structure In Dehradun:

Pre-engineered buildings have many advantages and these advantages include reducing construction time. The various benefits are as follows:

- Pre-engineered buildings have a predetermined list of raw materials. It has met a wide range of structural and aesthetic requirements. The components are pre-engineered and standardized. The use of customized software for design and drafting reduces the pace of the project, which is why it is good for construction in Dehradun.

- The design time of pre-engineered buildings is reduced because they are made of standard sections and connections. The low-weight flexible frame provides high resistance to seismic forces.

- The advent of the systems approach leads to savings in design, construction, and site construction costs. The structural diagrams of PEBs are shaped in such a way that they follow the stress diagram and thus reduce the weight cost, and load of the foundation.

- Pre-engineered buildings are approximately 30% to 35% lighter than traditional steel structures. pre-engineered building foundations are made of simple designs and are easy to construct with lightweight, which is also the reason for the increasing demand for PEBs in Dehradun.

- In the case of pre-engineered buildings, can be easily expanded in length by adding additional bays. Expansion in width and height is possible if you pre-design for future expansion.

- The connections of all the components used in pre-engineered buildings are standard and thus the construction time is fast which is helpful in rapidly growing construction in Dehradun.

- Quality control is completely assured in the case of pre-engineered buildings as the buildings are manufactured in the factory under completely controlled conditions.

- The paint systems for the cladding and steel are of high quality to suit the ambient conditions on site. This results in longer durability and lower maintenance costs.

- The complete building package of pre-engineered buildings is supplied by a single vendor. Thus the compatibility of building components can be completely ensured.

- pre-engineered buildings can withstand even the most severe storms. It has the highest durability. These PEB buildings provide the best warranties in the construction industry. These PEBs are growing rapidly in Dehradun.

Disadvantages of Pre-engineered Building Structures in Dehradun:

- If not properly maintained it can be prone to rust.

- Although Steel is a good conducting metal it reduces the thermal comfort of the building.

- This type of building becomes more vulnerable to fire and damage due to its conductivity.